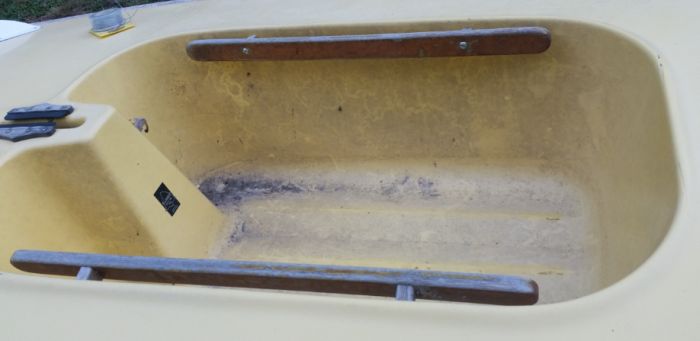

Barnett Butterfly Toe Rail Repair

Article By Stephen Truska

In the process of refinishing my toe rails, I thought I would remove them and to sand and varnish the small spacer blocks as well. I quickly found out this was not a good idea, as a quick search on the internet advised never removing these bolts. The bolts thread into an aluminum plate on the inside of the hull. Once the bolt is removed, this plates drops down into the hull, and there is not a good way to re-locate it to thread the bolt.

Luckily, I happened upon an article by Mark Suszko who devised a method to re-attach the toe rails. This gave me great hope, but I was not keen on the idea of cutting the hull to locate the plates.

I contacted a Butterfly expert to talk through my idea of using a wire and magnets to locate a nut on the inside of the hull, and I was told it would never work. The following is a record of my failures and ultimate success on securing my toe rail.

Feeling defeated and trying to avoid cutting an access port, I figured I would attempt to locate a nut inside. My first attempt involved using epoxy (JB weld) to secure a washer to a nut, then locate this to the inside of the hull by fishing a wire from the toe rail hole to the drain plug at the stern (I had recently enlarged the original ¼” drain plug hole to about 1” to accommodate the newer style drain plug. I was able to ball up a long metal wire and fished this through the hull using a powerful magnet on the end of metal rod (magnet from Amazon, metal rod from Home Depot). I was planning to use a modified bolt to pull through and center the plate inside the hull.

I was able to apply JB Weld to the washer surface and pull it through the hull using the wire. I attached a wire to the bolt so I would be able to retrieve it after adhering the nut. Unfortunately, this method failed. The epoxy did not stick to the fiberglass hull. I figured I would gain more surface area to epoxy if I used Marks method with a nut and a plate.

I used ample JB Weld on the back of the plate, but sadly, attempt number 2 also failed. The plate did not stick to the hull (looking back, Mark had success using gorilla glue, I may also have had success is I had used the proper adhesive). Additionally, the nut separated from the plate – I did not “rough up” the surfaces of the plate and nut with a file or sandpaper.

My third attempt was nearly identical to the second, however I properly scuffed the surfaces of the plate and nut before applying JB weld. This did the trick. I pulled the assembly through the drain hole, and against the inside of the hull. This time, I used the powerful magnet on the outside of the boat to hold the plate against the hull. I snipped the wire and held my breath. I CAREFULLY pushed the small length wire back into the hull. The nut was not perfectly lined up with the hole, so I used a small pick (small screwdriver would also work) to line this up before attempting to thread the bolt. I again CAREFULLY and slowly moved the toe rail, spacer block, and bolt into place. I began to turn the bolt and was ecstatic when it caught the threads on the nut. After this, I was able to tighten the bolt and I had a toe rail that was as good as new (well, I still had to do some sanding and varnish).

I am much more pleased in this method compared with cutting an access port in the boat. Please feel free to contact me with any questions and I’d be happy to try and help. Happy sailing!

-Stephen

stephen.j.truska@gmail.com